Development of CO2 auto design requires-. Slightly sand off the edges at one end and drill a hole in the other.

Dragster Design Washington Technology Student Association

It is one of the easiest models to make.

. A streamlined shape and selection of light material for construction are important factors taken into account. To design and study of aerodynamics co2 car. Up to 24 cash back Types of CO2 Dragsters.

Science of Speed 2 Design for Speed Poster. Well cover this in a bit. Making a Fast CO2 Dragster.

CO2 Dragster Middle School Maker Project. Drag - air resistance that pushes against a vehicle. They are designed for speed and use CO 2 catridges for power.

Of the Co2 car surface. Custom Cruiser Vehicle Design Kits. 1042010 17 Rail Cars Pros.

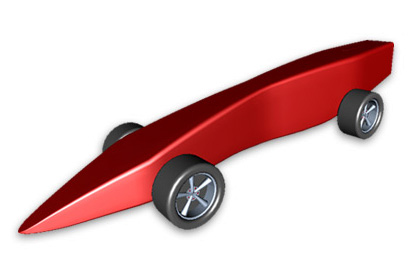

CO2 Dragsters Getting Started Package. CO 2 DRAGSTER DESIGN AND CONSTRUCTION Notes for Students Shell Cars the wheels hidden inside the body EXAMPLES OF DRAGSTER SHAPES AND STYLES Rail Cars the wheels outside the body Shell Reveal the wheels inside body extensions Hybrids. How do you make a Dragster.

Physics- the study of matter in motion. The goal is to make the dragster that moves the fastest. The gas escaping from the CO2 cartridge in the car.

Aerodynamics- the study of how solid objects displace fluid air and other gases. The 65-mph speed is also fast. This annual STEM event allow.

They are designed for speed and use. Race Car Dragster Co2 Solid Works. 1042010 5 CO2 Dragster Video CO2 Dragster Video.

This design for a dragster miniature has wheels that are externally placed and an extremely narrow chassis. CO2 drag cars are far more similar in design and principle to jet-powered land speed racers than they are a fuel car. The criteria to consider is wind resistance and friction both can slow down the car.

The more aerodynamically stable the design of the car the lower the drag faced. What are important qualities to consider when designing a CO2. Thin rails reduce weight of the car increasing speed.

Insert the handle into the power plant housing of the car body so that the timber jams slightly against the sides of the power plant hole. The speed of this vehicle is 7 kilometers per hour. The gas escaping from the CO2 cartridge in the car.

The cars can travel nearly 70 miles per hour 112 kilometers on the 5-foot 20-meter track in just over a second. It is difficult to create an extremely aerodynamic car. This type of racing involves the creation of a small carbon dioxide cartridge in the car which propels it down a flat level track.

The process of designing a CO2 dragster is crucial in making it move faster. The study of air is the effect of wind current and the powers included whilst an article travels thru the air or when air. How Fast Does A Co2 Dragster Go.

Keep these specifications in mind when completing the design process for you CO2 dragster. Forces That act upon a Co2 cars Lift - an upward force resulting from air being forced underneath a car. Simply put the less weight your dragster has the faster it will go.

CO 2 dragster cars are model dragsters cars. Tribology- the study of friction. What is the most important factor in a CO2 dragster design.

The second most important fact youll face. Up to 24 cash back CO2 dragsters have a small canister of CO2 in the back which once unleashed the car moved forward or the direction its pointed at. And the Fusion is Technology Student Association TSA approved for CO2 dragster competition.

They can outfit their dragster with one-of-a-kind designs and custom finishes. In a rail design the wheel and other parts of the dragster are exposed which naturally increases the drag. Thrust - a forward force produced by an engine or turbine.

You will be given class time to use the Internet to search for information about CO2 dragsters. The 65-mph speed is also fast. Research Step 2.

Simply put the less weight your dragster has the faster it will go. The Dragster Body Basswood Body Blank 12 in long. STEM Learning Activity CO2 Dragsters.

This video walks through the new Fusion CO2 dragsters. Top Fuel dragsters look the way they do because their primary design criteria is to channel more than 8000 horsepower through a little bit of rubber. The design is also such that it causes a reduction in the mass of the car thus increasing speed efficiency.

The iSTEM Need for Speed CO2 Dragster e-portfolio was designed for Mandatory Technology however the resource can be easily adapted for an iSTEM Learning Activity. This is the most important factor that will figure into your design. This type of racing involves the creation of a small carbon dioxide cartridge in the car which propels it down a flat level track.

Cut a 500mm length of flat cut 5mm X 18mm approx timber. In order to keep the competition fair and for the safety of the entire class there are certain specifications that must be followed by all students. Designing the Body of Dragster.

Make up a handle and hanger. Gravity - force acting on a car trying to hold it down to the earth. Science of Speed 2 Lets Get.

Design Process Step 1. Research and Development Objectives Research in CO2 auto design involves the study of a few sciences related to the motion of your dragster. This is the propelling force behind a CO2 dragster and is based on Newtons Third Law of Motion that states that for every action there is an equal and opposite reaction.

Sample CO2 Dragsters E-Portfolio 2 MB. Obviously this is how large and heavy the car is. What is a CO2 Dragster.

Dragsters that use CO2 as a propellant move when CO2 is escaping. The purpose of the CO2 dragster competition is to provide a means for students to demonstrate their ability using the design make and appraise principals to draw design and then build a dragster within a set of specifications. Explanation of the designing process should provide some idea about how to increase the speed of CO2 dragsters.

On Friday February 7 2020 South Junior High School hosted the annual Boise School District Tech 9 Co2 Dragster Championships. Dragsters that use CO2 as a propellant move when CO2 is escaping rapidly from the cartridge that is placed in the car. Perhaps the biggest misconception behind CO2 dragster design is in the name itself.

CO2 cartridges for power. Other factors to consider are weight and surface area of the dragster. Students are able to design and shape the polyurethane foam dragster using power or hand tools.

Science of Speed Pre-Assessment 154 KB. This is the most important factor that will figure into your design. Easiest to build and design.

Aerodynamics- the study of how solid objects displace fluid air and other gases. INTRODUCTION An essential thought in outlining a car is aeromechanics. Speed at any price show-stopping good looks or some combination of the two.

Science of Speed 2 Design Loop Poster. The cars can travel nearly 70 miles per hour 112 kilometers on the 5-foot 20-meter track in just over a second. Physics- the study of matter in motion.

Tribology- the study of friction. CO2 dragster cars are model dragsters.

Crazy Fast Ghs Co2 Powered Dragster S Design S And Races Youtube

Co2 Dragster Derby Engineering Design Technology

Dragster 2 0 Co2 Car Stem Software Application Whitebox Learning

Co2 Dragster Technology Engineering Design

0 comments

Post a Comment